How to optimize system efficiency through precision gasketing

Precision gasketing helps to achieve sustainability objectives at the system level by reducing waste and increasing equipment longevity

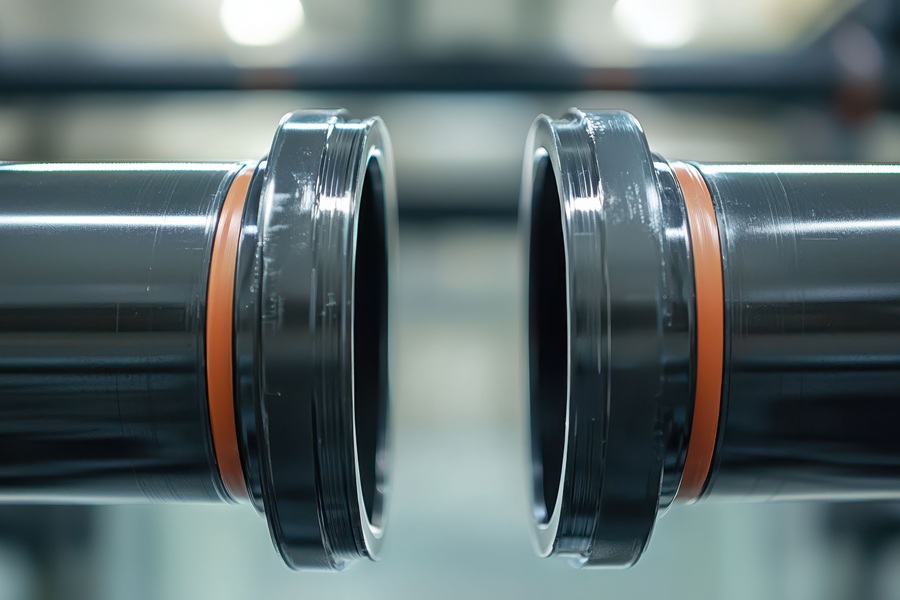

IN BOTH INDUSTRIAL activity, optimization of system efficiency is a concern in areas where energy loss, leakage and unplanned downtime directly impact on performance and cost. Accurate gasketing is one of the deciding factors of the condition of stability of the operating conditions due to the reliability of the seals on joints, flanges, and enclosures. When it is viewed not as a commodity item but as an engineered component, gasketing can help make the operation smoother, minimize wastes and also increase the life of the equipment. Learning the impact of precision gasketing on system behavior is the initial move to significant efficiency improvements.

Role of Precision Gasketing

Precision gasketing is conducive to efficiency because it provides regular and reliable performance of sealing under specified working conditions. Well adequately designed gaskets are tight seals meaning that they do not allow leakage of fluid, gas or thermal energy, they allow systems to run at the desired pressure and temperature. This stability limits the corrective adjustments made to the system and lowers the wastage of energy which is lost to systems in an attempt to balance the leaks or drop in pressure.

In addition to sealing, precision gasketing enhances loading of mating surfaces. Equal compression aids in averting flange deformation and unbalanced pressure, which will result in misalignment and early wear. Through correct alignment and contact, systems will be able to run near their design parameters, which contributes to reliable flow control and consistent output.

Impact on Energy Control

The efficiency of energy is very much connected with the ability of a system to retain and channel heat and pressure. Precision gasketing lowers unwanted energy waste by closing routes which pass on heat or pressure. In thermal systems, gasketing should be used effectively to supplement other control methods in order to establish boundaries which promote the performance of insulation, and process stability.

Where there are high temperatures, gasketing should be used together with other materials like ceramic fiber insulation to reduce heat loss. In cases where gaskets are accurately issued to temperature and pressure limits, they contribute to saving thermal efficiency and lower energy used to keep operating temperatures as time goes by.

Material Selection Factor

Choosing the right gasket material is the key to high efficiency. Materials have to work with media, temperature, pressure, and mechanical loads in order to work uniformly. Accurate gasketing is based on tight manufacturing limits and material characteristics that provide consistent compression and recovery characteristics that minimize the risk of leakage and performance drift.

The material selection also has an impact on the gasket interaction with the surrounding parts. Fabric fiberglass can be considered in other related sealing or insulation applications that demand flexibility and strength in systems. The alignment of gasket materials to the requirements of the system makes seals stable and efficient during the operating cycles.

Installation and Load Control

The most developed gasket design cannot present any efficiency gains without appropriate installation. Precision gasketing entails controlled bolt load and uniform compression in order to attain optimal sealing. Excessive compression may cause gasket damage and may also cause surfaces to leak and wastage of energy.

Regular installation ensures consistency and lowers assemblies variability. In cases where load control is standardized, systems have less performance deviation, which facilitates stability in operation and also less rework or retightening which disrupts efficiency.

Maintenance and Monitoring Practices

Continued efficiency relies on observing the state of gaskets. With precision gasketing the wear patterns are more predictable, therefore it is easy to plan the maintenance before the performance deteriorates. Frequent checks assist in detecting early signs of loss of compression or material degradation which might influence the efficiency of the system.

Operators can prevent unexpected failures that result in energy wastages and downtimes by incorporating gasketing checks in the regular maintenance programs. Long term efficiency is served by proactive maintenance seeking to maintain the seal in operation.

System Level Benefits

With the application of precision gasketing, the efficiency can be improved not only in each part. The systems have the advantage of consuming less energy, are more reliable, and their processes are more stable. The gains lead to reduced operating costs and greater performance in general.

Precision gasketing of systems helps to achieve the sustainability objectives at the system level by reducing waste and increasing equipment longevity. Organizations can achieve an optimized system efficiency in a measurable and sustainable manner by paying attention to proper design, choice of materials, installation and maintenance.